Forming difficult curves

Bétta's glass baby bottles are made by the following process

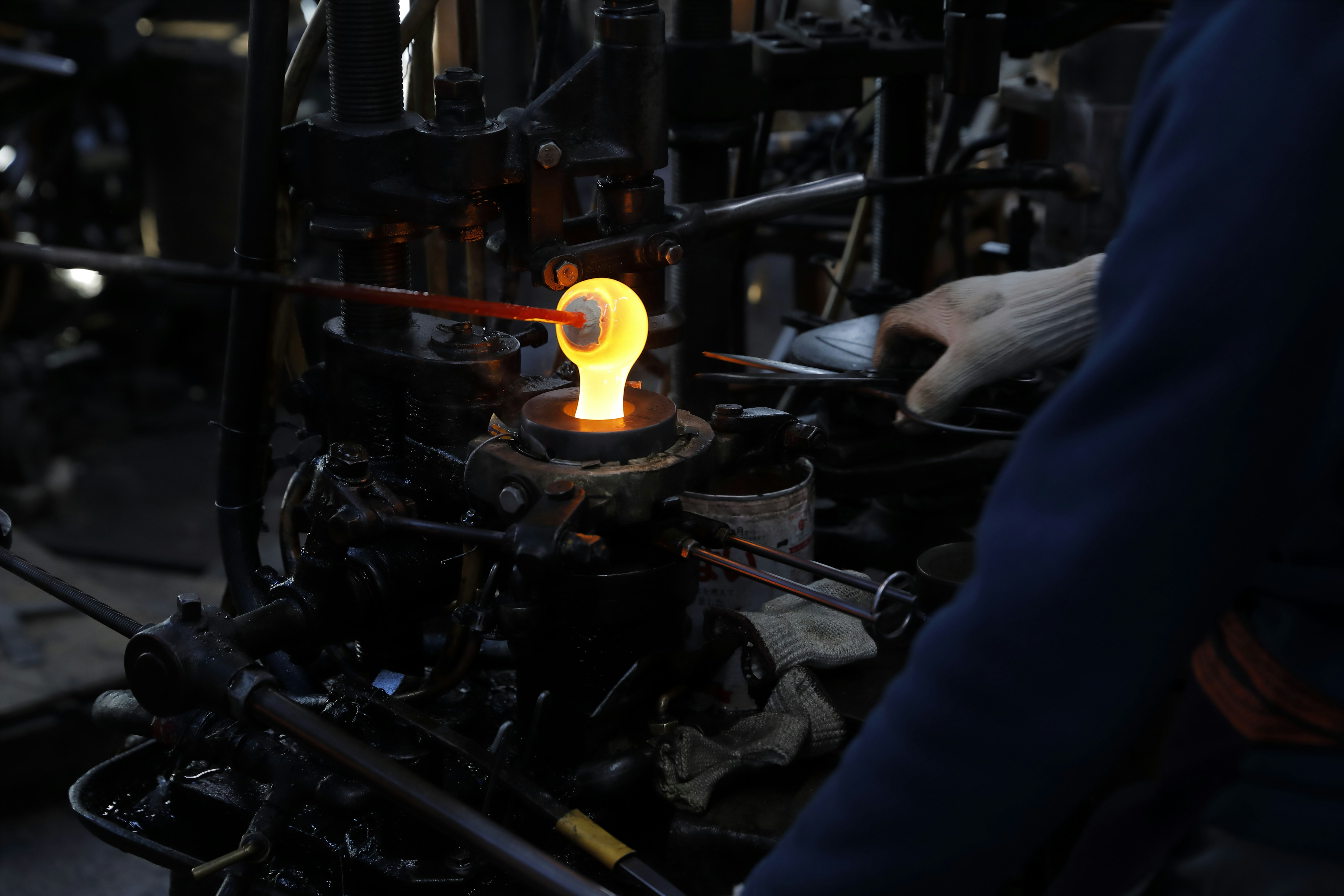

Heat-resistant glass Dr. Bétta bottles are made by boiling down in a high-temperature furnace at 1500 degrees Celsius. It must be boiled down for a few days before it can be put into production. The first craftsman gently scoops up the boiled-down sludge with a long stick called a ponte, while the second, as it falls down the ponte, quickly cuts it out with scissors and puts it into the first mold. The third person sees that the material in the betta mold flows down moderately and closes the mold that is broken in two. Then air is put into the mold, wait for a few seconds, and open the main mold to make a Bétta bottle. The "Dr. Bétta bottle" made of heat-resistant glass is manufactured by such a long process. This is the moment when you can truly feel the warmth of hand-painting.

1. Winding the glass, the most important part of the process(There will be air bubbles during this process.)

2. Pour into the first molding machine and make a rough shape.

3. It is transferred to the second mold and air is blown into the shape of the curve of Bétta.(There are lines and streaks in the material as it flows.)

4. Slowly de-cool a hot glass bottle over time.(There are traces of wire mesh on the bottom of the bottle at this time.)

5. After visual inspection, it is measured strictly with calipers and measuring instruments. Finally, it was examined by tapping it hard with a wooden hammer.

6. Fresh-made Dr. Betta bottle. Complete with a smooth curve.

It has a " unique individuality" that can be found only in handmade products.

Each of Dr. Bétta's glass baby bottles are hand-formed, so each one has its own unique individuality. In some cases, bubbles and streaks may be present, but during the inspection, we measure the weight with a caliper, check the size of bubbles and the degree of streaks, beat the entire product with a wooden mallet, and visually inspect all the products with large astronomical glasses under bright light, and only products that meet the safety standards are shipped. Even if there are bubbles or streaks as shown in the photo below, there are no problems with the strength or safety of the product under normal use.

These are bubbles that are generated when the glass is rolled up and there may be some bubbles in one bottle.

There may be streaks when the glass is rolled up, and there may be a large undulation when the glass cools and hardens.

There may be traces on the bottom when placing a freshly molded, still soft bottle.